|

|

|

|

|

Sales |

| Call: 0918 846 288 |

|

|

|

|

Support Online |

| Call: 0908 880 788 |

| |

|

| |

|

|

|

|

| Bag Making >

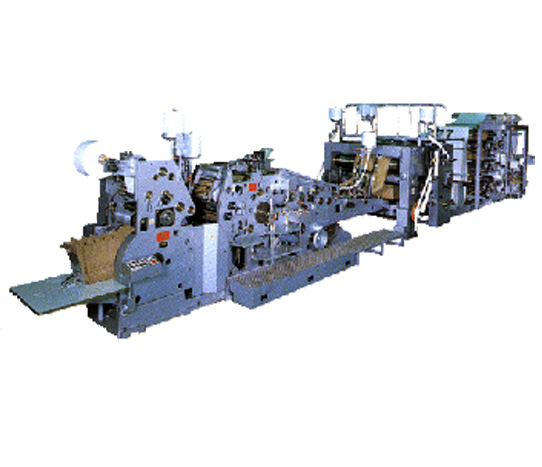

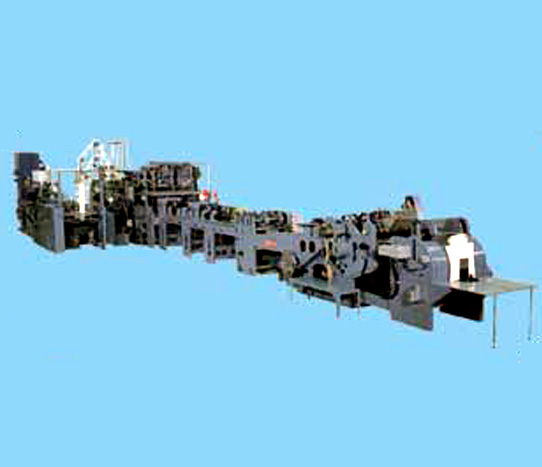

BAG MAKING Model : 21M |

|

|

BAG MAKING Model : 21M |

|

PP/PE BAG

HIGH SPEED PLASTIC BAG TUBING MACHINE |

|

|

|

| Specifications |

|

|

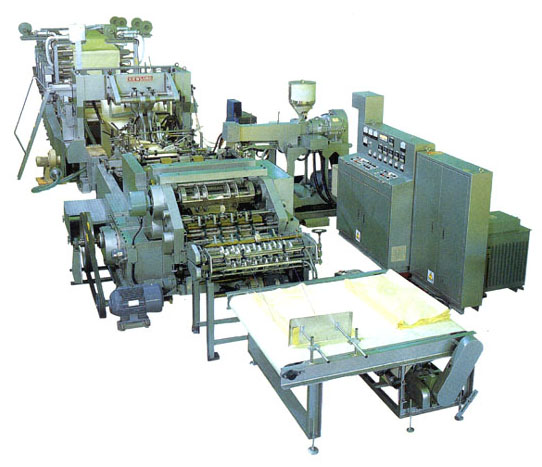

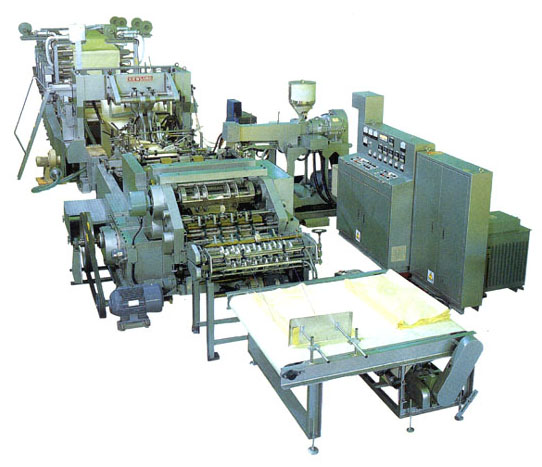

Pasting Unit with Extruder Pasting Unit with Extruder |

|

| Machine Construction |

Cloth Roll Stand

* The machine has two Cloth Roll Stand and while on stand is in operation, another stand can be used for installing stand-by cloth roll.

* EPC ( Edge Position Controll ) Device controls the position of Cloth Roll Stand laterally.

* The break pressure can be adjusted by Friction Brake manually. |

Plastic Extruderr

* Plastic resin as the bond is melted by Plastic Extruder and it is jetted to the portion of cloth to be bonded.

* Another EPC device keeps jet nozzle in accurate position,

* The jet quantity of bond is freely adjusted by a Variable Speed Motor. |

Tube Forming and Bonding unit.

*The cloth coming from Roll Stand is formed into the tube by means of several rollersand quide plates.

* After bonded, the seam is pressed by Rubber Roller of 200mm diameter and cooled by Cooling Rollers. |

Cutting Unit

* Both shear cutting and heat cutting are available by changing cutting knives. By using Photo Cell Device, the cutting length can be adjusted to the register mark. |

Delivery Belt Conveyor

* Finished tubes bonded and cut are delivered out by Belt Conveyor, speed of which is freely controlled by Variable Speed Motor.

The Delivery Belt Conveyor has Automatic Tube Counting Device. |

Inner PE Tubular Film Device (Optional)

* Connsists of two PE Tube Roll Stands (one for spare), Auxiliary Web Draw Unit,Cross Pasting Unit, etc. |

Inner Kraft Paper Device (Optional)

* Consists of two Cloth Roll Stands (one for spare) , Tube Bonding Unit, Paper and Cloth Pasting Unit, etc. |

| Other optional arrangements are also available on request. |

| |

- Bags Available (Additionally)

Apart from the basically available formats mentioned with figures here, the following is also available as optional.

Circular Woven Bottom Sewn Bag. (Format A in page No. 10) |

| SPECIFICATIONS |

| Cloth Roll Width |

Max.1,440 mm ( 56 3/4") |

| Cloth Roll Diameter |

Max. 1,300 mm (50") |

| Cutting Length |

597-1,397 mm (23 1/2-55") |

| Tube Width |

381-700 mm (15-27 1/2") (without gusset) |

| 381-495 mm (15-19 1/2") (with gusset) |

| 450-600 mm (17 3/4-23 5/8") (with inner PE tube) |

| Gusset Width |

Max. 152 mm (6") |

| Speed |

Max. 150bags/min (Shear Cutting, without gusset.) |

| Max. 110bags/min (Heat Cutting) |

| Max. 120tubes/min (Shear Cutting, with gusset &Valve) |

| Electricity |

| Main Motor |

15kW 1set (with printer) | |

|

|

|

|

|

|

|

|

| Net Weight |

Approx. 19,700kg |

| Gross Weight |

Approx. 27,000kg |

| Measurement |

Approx. 3,700cft | |

* (As improvements are introduced from time to time, we reserve right to make alternations.)

* the actual operation speed depends on operating conditions, material cloth quality, beam conditions, labour quality, etc. |

| Bags Available |

|

|

|

1. PP/HDPE Woven Cloth Bag (with or without Lamination |

| 2. PP/HDPE Woven Cloth Bag (with Inner PE Tubular Film Bag |

| 3. PP/HDPE Woven Cloth Bag laminated with Inner(or outer) Kraft Paper, Open Mouth Type. (PAPER-CLOTH BAG) |

| 4. PP/HDPE Woven Cloth Bag laminated with Inner(or outer) Kraft Paper, Both End Sewn, Valve Mouth Type. (PAPER-CLOTH BAG) |

| 5. Multi-Ply Kraft Paper Bag. (Various combination of Laminated Kraft-paper or Culpac-paper.) | | | |

| |

<< Go back |

|

|

|

|

Pasting Unit with Extruder

Pasting Unit with Extruder