|

|

|

|

|

Sales |

| Call: 0918 846 288 |

|

|

|

|

Support Online |

| Call: 0908 880 788 |

| |

|

| |

|

|

|

|

| Bag Making >

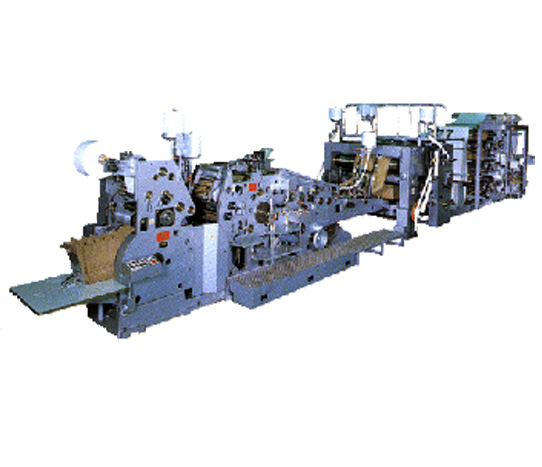

BAG MAKING Model : 335T |

|

|

BAG MAKING Model : 335T |

|

SOS BAG

SHEET-FED SHOPPING BAG MAKING MACHINE |

|

|

|

| Specifications |

| Combined with a handle making machine, this machine attaches carrying handle to the top of a sheet, folds the bag mouth to paste it together, and makes high class square-bottom (S.O.S.) bags with handle after longitudinal pasting and bottom pasting by a completely automated process. |

| This machine attaches handles automatically, folds the bag mouth, and makes strong beautiful square-bottom (S.O.S.) bags. Capability of making beautiful, high class carrying bags somewhat

different from the conventional bags with string (cardboard not

pasted).

• Capability of making much stronger carrying bags than the

conventional ones because the handle is firmly secured.

• Safety and high efficiency because the handle does not come off in

the longitudinal pasting and bottom pasting processes.

• The handle stands erect when the bag is completed, providing

asethetic appeal and easy handling. |  |  | 1 Cutting the notch for the handle. |  | 2 Pasting the mouth to be folded. |  | 3 Applying the handle on the pasted mouth. |  | 4 Pressing after folding the mouth. |

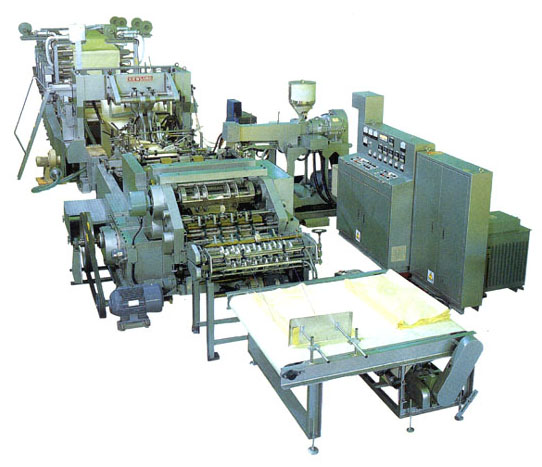

| | | |  | |  | | 1 Notch for ht handle. | | 2 Pasting the mouth to be

folded. |  | |  | | 3 Applying the handle on the pasting mouth. | | 4 Folding the mouth, pasting

the notch lip for the handle and pressing. | | |  | It can also make square-bottom (S.O.S.) bags with a punched hole after pasting cardboard and folding the mouth. | | An automated type is available, which pastes cardboard at two specified positions of a sheet, folds the top of the bag mouth, form, it into a tube, and makes punched holes ofr threading by a completely automated process. | |  | | 1 Forms a tube after pasting cardboard and folding the mouth. | | 2 Make a punched hole for threading in the cardboad after pressing. | |  |

1 | No problem of paper jamming in the transfer process

The machine is designed to prevent jamming and ensures accurate transfer of paper, resulting in no loss or waste of paper. | 2 | High speed,high performance, and fully automated operation

For example, Model 322T has a capacity of making 120 bags per minute. The greatly improved operational efficiency will also contribute to labor saving. | 3 | Reduced troubles and improved durability of component parts

Stringent quality control in the design to the final inspection stage has reduced machine troubles and improved abrasion resistance and durability of the component parts. | 4 | Manufactured by NC machine tool

The machine is constructed with a computer-controlled high precision machine tool and offers a significantly improved degree of perfection in all respects. | 5 | No drawbacks of sconventional machine

The machine features high quality with no drawbacks at all which occurred in the conventional machines. | 6 | Easy size change and no waste of bags

The bag size can be easily changed by just an adjusting handle, and there is no waste of bags |

|

|

|

| |

<< Go back |

|

|

|

|