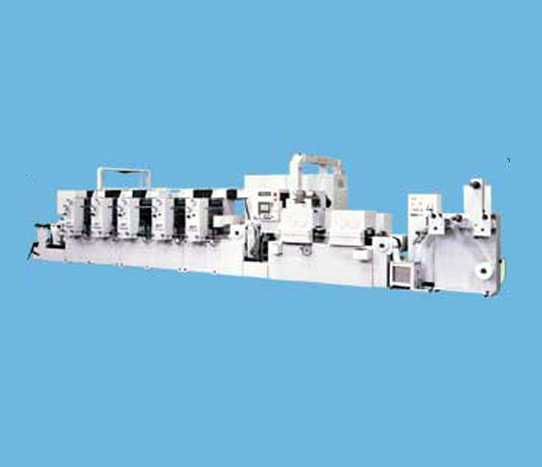

| Perfect registration on multiple passes through the press. Modular design with many optional attachments for combination printing. |

| The superiority of offset. | • PO3 offset-litho printing is renowned for its high quality of plate dot.

• Inking train by computer aided analysis for high quality printing.

• Skew system.

Plate can be twisted without lifting and stopping the press.

• Even ink flow to be provided by oil cooling unit.

• Ink suply control by C.I.P (computer ink program) when changing the running speed. |

| |

|

|

| | Easy operation by centralised control panel. | Ideally swited for the production of short to medium run lengths.

Computerised control over all Operations is though a touch screen control panel.

(e.g. speed, printing length, cutting ratio options ON/OFF etc)

Quick change of plate cylinders.

In case of start up problems, a self diagnostic feature immediately identifies the problem allowing the operators to take appropriate action. |

|

|

|

| Stable and precise print register and minimum waste. | Twin vacuum draw cylinders at each end of the printing section hold the web tension in a streight web path.

Web tension can be easily controlled via a touch screen and there for reduces waste. |

| |

|

|

| | FD unit and Hot foil stamping unit (option). | Heavy duty Rigid construction of flatbed die cutting unit operates at up to 300 imp/min.

Easy set up without makeready.

An electric photocell ensures perfect print-to-cut register. |

| |

|

|

|

| Slitter and rewinder unit (Option). | Slitter and rewinders with a rotary (continuous feed).

It offers scissor slitting, waste stripping and rewinding labels in or out with variable tension control Options include back slitting, perforating and heater plate units.

|

| |

|

|

PO3-270 350 | Specifications

| | PO3-270 | PO3-350 | | Printing Process | Offset | Offset | | Plate type | Waterless photopolymer plate | Waterless photopolymer plate | | Printing area (max.) (LxW) | 254x254mm | 254x331mm | | Number of printing stations | 3 ~8 | 5 | | Repeat length ( Length increment 0.1mm) | 120 ~ 260mm | 120 ~ 260mm | | Web width | 110 ~ 270mm (4.3" 10.6") | 177.8 ~ 350mm ( 7" ~ 13.7") | | Maxmum roll diameter | 800mm | 800mm | | Operating speed | 20 ~ 150/120imp/min* | 20 ~ 150/120imp/min* | | Die-cutting method | Flat die-cutting unit | Flat die-cutting unit | | Die cut area (max.) (LxW) | 254x254mm | 254x331mm | | Length of cutting rule (max.) | 2500mm (Maximum pressure 49000N) | 5000mm (Maximum pressure 49000N) | | Printing/die-cutting ratio | 1:1, 1:2, 1:3 | 1:1, 1:2, 1:3 | | Machine dimensions(LxWxH) | 6355x1445x1590mm (4 color) | 9000x1750x1590mm (4 color) | | Machine weight (approx.) | 5700kg (4 color) | 8500kg (4 color) | | | | Option | - 2ND flat die unit

- Hot foil stamping unit

- Flexo-varnish unit

- Flexo-printing unit

- Back printing unit (letter press)

- Laminating unit

- Magnet-die cylinder unit

- Slitter-rewinder

|

|

|

|

|