|

|

|

|

|

Sales |

| Call: 0918 846 288 |

|

|

|

|

Support Online |

| Call: 0908 880 788 |

| |

|

| |

|

|

|

|

| Printing >

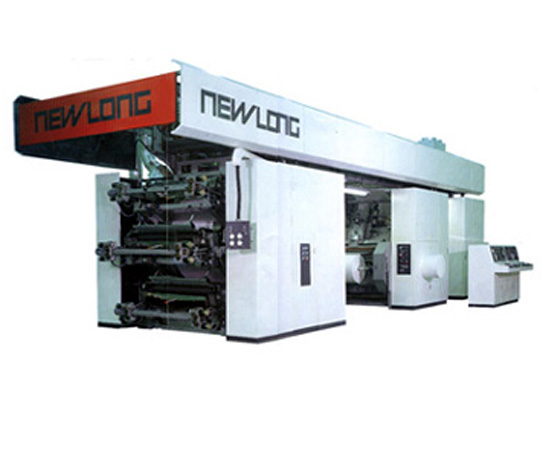

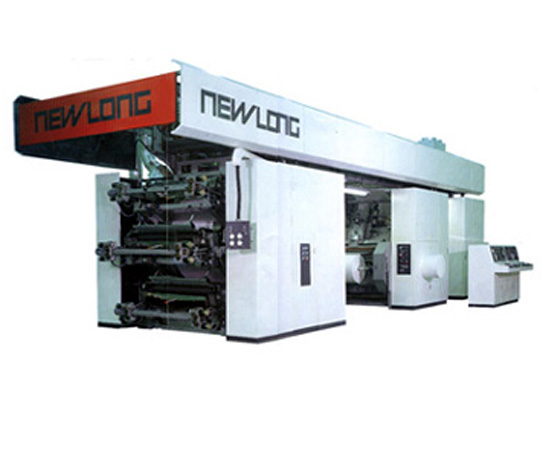

PRINTING MACHINE Model : HI-FLEX |

|

|

PRINTING MACHINE Model : HI-FLEX |

|

Printing Machine

CENTRAL IMPRESSION

FLEXOGRAPHIC PRINTING

PRESS 6 COLORS |

|

|

|

| Specifications |

| COMPUTERIZED FLEXOGRAPHIC PRESS FOR PRECISE PRINTING | CHARACTERISTICS

CHARACTERISTICS - Robust frame (120mm thickness).

- Precise rolls and frame (T.I.R. of central impression cylinder +-2.5u)

- Running register, impression, nip pressure are controlled numerically by computerr. (CNC)

- Web tension control by AC vector (AC servo drive)

- Doctor chamber colour deck.

- All kinds of printing materials such as paper,PE/PP, OPP available.

- Accurate register control achieved for precise central impression cylinder.

- Gears of printing unitare finished grinding.

- Impression cylinder surface is processed with anticorrosive coating for easy cleaning.

The surface temperature is kept adequate by hydraulic temperature control. - Ceramic anilox roll (500 lines/inch) applied, so printing of 100~133 lines/inch available.

|  |  | - CNC Colour Deck Positioning System

| - Doctor Chamber Colour Deck

| |  |  |  | | | |

SPECIFICATIONS | | 613FH | 616FH | | Max. web width | 1,320mm | 1,600mm | | Max. printing width | 1,270mm | 1,570mm | | Printing length (10mm pitch) | 300~ 960mm | 400~ 960mm | | Max. printing speed | 200m/min. | | Number of colour | 6 | | Max. web diameter (unwinder) | 1,100mm | | Max. web diameter (rewinder) | 1,100mm | | Unwinding tension | 30 kg/whole surface | | Rewinding tension | 50 kg/whole surface | | Drying system | electriity , gas, steam | | Printing materials | | kraft paper | 40 125g/m2 | | PE/PP film | 0.02 0.15mm | | PE Tube (Total thickness) | 0.03 0.15mm |

| kraft paper 50 140g/m2 |

*Specifications subject to change without prior notice

OPTION - CNC Control

- Doctor Chamber colour Deck

- Ceramic Anilox Roll

|

|

|

|

| |

<< Go back |

|

|

|

|